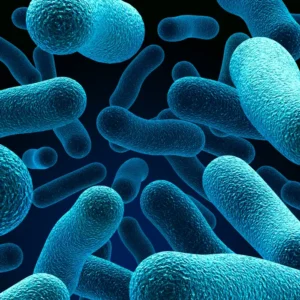

Microbial Fermentation Services

Your CDMO Partner for Microbial Fermentation Services

Providing microbial CDMO solutions for our partners means that we work with you to deliver scalable, robust and commercially viable processes that meet your future market demands.

For a range of microbial hosts (E.coli, P. pastoris, S. cerevisiae), we create flexible, modular plans to take you from strain selection, through process development and to commercialization.

Across our global network, access unsurpassed experience in difficult-to-express proteins, potent APIs and various PEGylation / conjugation chemistries coupled with a strong regulatory track record to deliver the project you need, when you need it.

Efficient, Proven and Effective Microbial Offerings

Access Paveway PLUS, a well-proven, antibiotic-free modular platform that offers rapid strain selection based on parallel evaluation on product titer and quality, plus early pre-clinical material generation.

Our experts work with you to ensure that purification processes are developed and optimized with a line of sight to commercialization, so that your product achieves the maximum yield and quality possible.

Accessibility and flexibility in a choice of manufacturing locations and scales to meet your clinical and commercial requirements.

Analytical solutions to guide the clinical lifecycle and commercial manufacturing.

Leverage our experience in advancing vaccines from pre-clinical to commercial supply across multiple modalities.

Discover More About Our Microbial Facilities

At A Glance

Customer Success

High efficiencies of up to 25-fold increase in titers combined with remarkable long-term stability and customer service have been described by Theriva Biologics.”

White Paper • Paveway™ PLUS Microbial Expression System for the Efficient Production of Therapeutic Proteins